Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: 4YZP-4A

Brand: Gold Dafeng

Type: Horizontal Cut Harvester

Application: Corn

Power Source: Diesel

Harvest method: Cutting

Drive Type: Vee belt

Transmission: Hard Shaft

Certification: CE

Color: Green

Condition: New

Application Field: Agriculture

Horse Power: 160HP

Fuel Consumption: Less Than 40 Kg/hm²

Total Weight: 6350kg

Harvesting Rows: 4

Max.height Of Corn Lifter: 3360mm

Bin Capacity: 3.5m³

Dimension(L*W*H): 8100*2990*35500mm

Working Efficiency: 2666-6000m²/h

Applicable Row Width: 570-670mm

Returning Width: 2400mm

Packaging: Main body be naked, and the rest of it can be packaged by iron frame.

Productivity: 600 set per month

Transportation: Ocean,Land

Place of Origin: China(Mainland)

Supply Ability: 550 Sets/month

Certificate: SGS ISO9001

HS Code: 84335100

Port: Qingdao,Ningbo,Shanghai

Payment Type: L/C,T/T,Western Union

Incoterm: FOB,CFR,CIF

Main clutch usage and maintainance for Self Propelled Corn Picker. (1). Notice –- When control clutch transporte pwer, shoul connect slowly and leave fast, overexert or multiple point start might damage friction slices. Operator control main clutch cylinders should pay special attention to this point. (2). Clutch friction plate is asbestos material, forbid surface is stained with grease, otherwise, it will cause the clutch combine failure. Which request operator must keep friction slices working surface cleaning and drying, and prevent excess butter when maintain clutch bearing, to prevent spills flyblow friction slices. (3). Unclean screw put on clutch case bottom, often should put out casing oil or water, keep dry and clean. (4). Compaction lever, adjusting plate, linking slab, separation bushings pin hole and three lever pin wear abrade seriously, should change in time, otherwise, easy appear clutch output torque reduce, and separation is not clear or can`t be combined.(5). After work, should often check safty pin in control system fully or not through examing, split cotters or breaking off should seasonable compensatory, and lock reliable. Otherwise, easy cause fly pieces, and breake down shell. (6). After clutch work one week everytime, at least use grease gun to inject high speed grease into separation bearings, back shaft block bearing (high resistant temperature 150℃ Lithium level grease), also grease should be moderate.

4YZP-4A Self-propelled combine harvester

1. Short body length, small turning radius, flexible turning, high work efficiency.

2. Adopt turbocharged engine, high power and low fuel consumption.

3. Front mounted straw returning system avoids tires rolling the straw, good straw chopping effect.

4. Corn husker adopts 16rolls with unique guide flow device, high husking efficiency, fast harvesting speed, good husk effect.

5. Equipped with corn husk chopping system, which can chop the husk into small pieces after corn husking for returning to field.

6. Adopt corn harvester special used drive axle, stable and reliable performance, durable in use.

7. With electronic monitoring screen installed in the cab, the driver can monitor the situations in time, preventing tank overfilling and increasing backing safety.

Parameters for products:

| Model | 4YZP-4A | Bin capacity | 3.5m³ |

| Husking rolls | 16 | Snapping type | Corn stalk pulling roller +Snapping board |

| Working width | 2725mm | Power | 160 HP |

| Operating efficiency | 2666-6000m²/h | Dimensions | 8100*2990*3550mm (Length*Width*Height) |

| Number of the rows | 4 | Row width | 620mm |

| Returning type | Middle returning | Returning width | 2400mm |

| Applicable row width | 570-670mm |

| |

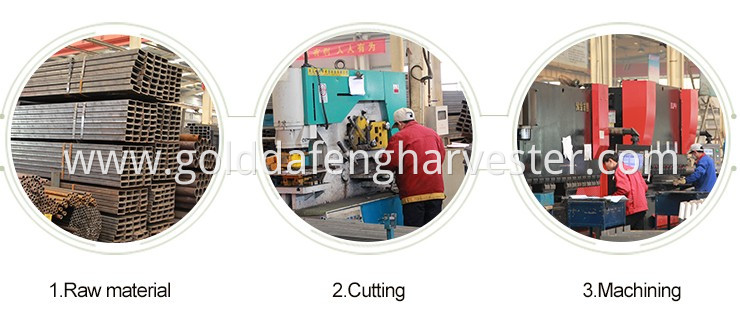

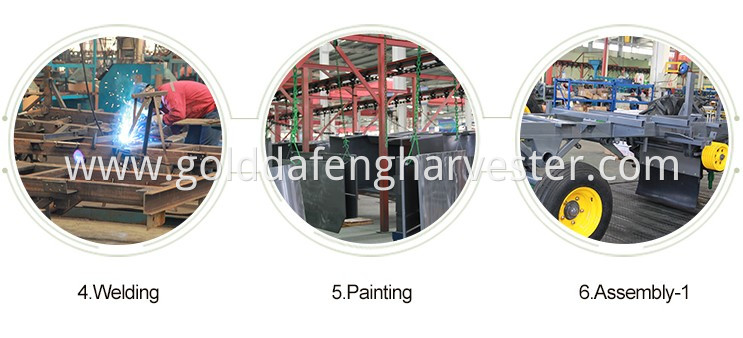

Workshop:

Product Line:

After-sales service

1.Warranty

Gold Dafeng grants our clients twelve-month-period warranty for any machine purchased from us which could reach the certain target quantity. During the warranty period, in case the defect of material or workmanship has occurred with Spare Parts in normal operation, the defective part will be repaired or replaced free of charge, at our discretion.

2.Spare parts

Gold Dafeng is dedicated to provide our clients with genuine spare parts with the highest quality, exact fitness and appropriate function. With our global distributor network, you are guaranteed with fast delivered and services, wherever you are, please submit your spare parts request to us, and list products name, model, equipment serial number, description of required parts. We guarantee that your request will be handled quickly and appropriately.

3.Installation&Maintenance

Gold Dafeng is able to provide you with the overall installation of complicated machinery and equipment, allowing you to start the normal operation of handling machinery immediately. After installation, we will make inspection of the whole machine, operate equipment, and provide you with testing data reports of installation and operation.

4.Training

Gold Dafeng offer perfect facilities and comfortable environment and can provide training service to different users. The training sessions include product training, operation training, maintenance know-how, technical know-how training, standards, laws and regulations training and other training, all of which are tailored to fulfill your individual needs. Training programs can be conducted in our factory field, or at the client`s site.

5.Technical advice

Gold Dafeng can also help clients coordinate with trained service personnel to provide you detailed and extensive knowledge about your specific machine. With our technical advice, your machine service life can be significantly prolonged and sustained with high capacity.

Our factory with more than 20 years of experience and innovation, including Hydraulic Pressure Disc Harrows, High Box Rotary Tillers, Self-propelled Corn Combine Cutter, self-propelled full feed Rice Combine Harvester, Farmer Tractor, Self-propelled Wheat Harvester and so on, offers one of the most complete lines in the industry.

Product Categories : Corn Harvester > Four Rows Corn Combine Harvester

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.