Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Model No.: 4YZP-4

Brand: Gold Dafeng

Type: Horizontal Cut Harvester

Application: Corn

Power Source: Diesel

Harvest method: Cutting

Drive Type: Vee belt

Transmission: Hard Shaft

Certification: CE

Color: Green

Condition: New

Application Field: Agriculture

Horse Power: 160HP

Fuel Consumption: Less Than 40 Kg/hm²

Applicable Row Width: 450-750mm

Bin Capacity: 2m³

Dimension(L*W*H): 7200*2500*3360mm

Total Weight: 6350kg

Working Efficiency: 0.4-0.65hm²/h

Harvesting Rows: 4

Max.height Of Corn Lifter: 3360mm

Min. Ground Clearance: 300mm

Packaging: Main body be naked, and the rest of it can be packaged by iron frame.

Productivity: 600 set per month

Transportation: Ocean,Land

Place of Origin: China(Mainland)

Supply Ability: 550 Sets/month

Certificate: SGS ISO9001

HS Code: 84335100

Port: Qingdao,Ningbo,Shanghai

Payment Type: L/C,T/T,Western Union

Incoterm: FOB,CFR,CIF

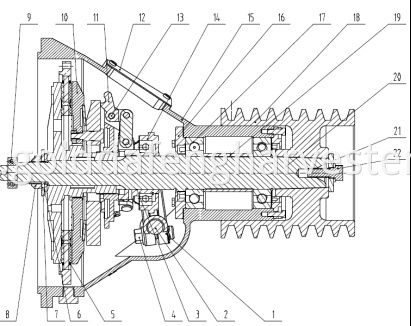

Main clutch fix on engine flywheel, through meshing of flywheel inside gear ring and friction disc, dynamic pressure fixing plate and friction disc friction transmit power. Main clutch is often open-type, monolithic, dry, adopt dished diaphragm spring elastic compensation.Working principle is as follows: Clutch is in separation condition, due to lack of power which makes clutch friction slices and combining parts produced friction, merely engine flywheel drive inside gear ring, inside gear ring drive friction slices riveting pieces of rotation, other parts of is in static state, eight slot pulley is motionless. Push forward active clutch oil cylinder control handle, separate bearing in ward slide under impact of gearshift forks, compaction lever promote pressure plate, make dynamic pressure plate, friction slices and rear dynamic pressure plate press toghter, and generate enough friction clutch disk, drive fixed pressure spline shaft rotate, thus promote eight slot pulley rotate. Main clutch is the most important structure part in Corn Harvester, correct debugging, maintenance, repair, use,which reduce work breakdown, prolong service life, increase harvest efficiency and reduce maintenance costs are very important . Operator should pay special attention to research and study of main clutch structure, thoroughly understand working principle,master each component function, strictly according to the technical requirements for disassembling and maintenance, correct operation, to avoid blindly use to bring losses.

1.Shifting fork 2.Declutch shift shaft 3.Fork lever 4.lock nut 5.Flywheelannulargear 7.level pressure locking plate 8.Level pressure plate lock nut 9.6205-2RS bearing 10.Platen connecting parts 11.Compact lever 12.Window cover 13.lever pin roll 14.release bearing connecting parts 15.clutch box 17.311bearing 18.Eight groove pulley 19.sleeve pipe 20.Clutch shaft 21.Check ring 22.Bolt

How to Harvest Corns?

1. After the corn stalks are guided into the gap of the counter-rotating rolls, they will be pulled downwards by the rolls, and the corncobs will then be snapped off for its large diameter.

2. The corncobs are conveyed into the corn husker by the lifting conveyor, while straws are chopped by the flail knives to return to field.

3. Husked corncobs fall into the corncob tank while husks enter into the corn husk chopping system .

4. Chopped husks are discharged from the outlet on the side of the harvester and return to field. When the corncob tank is full, the driver can turn it over conveniently to unload the corncob.

Parameters for Combine Corn Harvester:

| Model | 4YZP-4 | Bin capacity | 2m³ |

| Husking rolls | 20 | Snapping type | Roll type |

| Working width | 2310mm | Power | 160 HP |

| Operating efficiency | 4000-6466m²/h | Dimensions | 7200*2500*3360mm (L*W*H) |

| Number of the rows | 4 | Row width | 550mm |

| Returning type | Front cutting+ Middle returning + husk crushing | Returning width | 2250mm |

| Applicable row width | 450-650mm |

| |

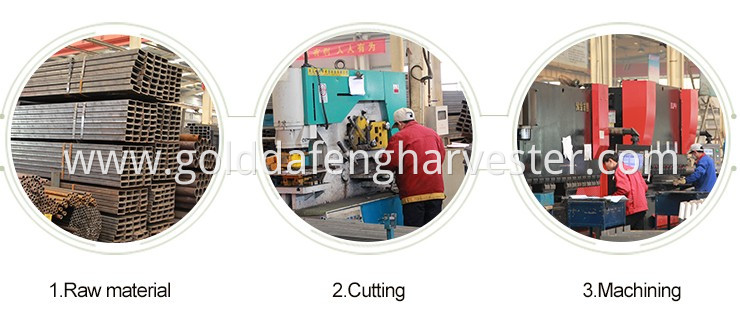

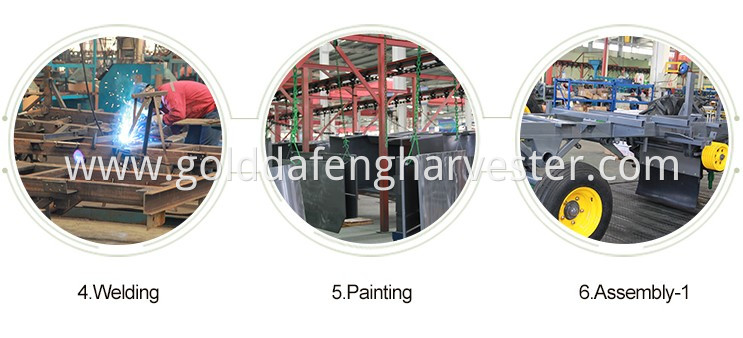

Corn Harvester Workshop:

Self-propelled Corn Combine Harvester Product Line:

Self-propelled Harvester After-sales service

1.Warranty

Gold Dafeng grants our clients twelve-month-period warranty for any machine purchased from us which could reach the certain target quantity. During the warranty period, in case the defect of material or workmanship has occurred with Spare Parts in normal operation, the defective part will be repaired or replaced free of charge, at our discretion.

2.Spare parts

Gold Dafeng is dedicated to provide our clients with genuine spare parts with the highest quality, exact fitness and appropriate function. With our global distributor network, you are guaranteed with fast delivered and services, wherever you are, please submit your spare parts request to us, and list products name, model, equipment serial number, description of required parts. We guarantee that your request will be handled quickly and appropriately.

3.Installation&Maintenance

Gold Dafeng is able to provide you with the overall installation of complicated machinery and equipment, allowing you to start the normal operation of handling machinery immediately. After installation, we will make inspection of the whole machine, operate equipment, and provide you with testing data reports of installation and operation.

4.Training

Gold Dafeng offer perfect facilities and comfortable environment and can provide training service to different users. The training sessions include product training, operation training, maintenance know-how, technical know-how training, standards, laws and regulations training and other training, all of which are tailored to fulfill your individual needs. Training programs can be conducted in our factory field, or at the client`s site.

5.Technical advice

Gold Dafeng can also help clients coordinate with trained service personnel to provide you detailed and extensive knowledge about your specific machine. With our technical advice, your machine service life can be significantly prolonged and sustained with high capacity.

About us:

Our factory with more than 20 years of experience and innovation, including Hydraulic Pressure Disc Harrows, High Box Rotary Tillers, Self-propelled Corn Combine Cutter, self-propelled full feed Rice Combine Harvester, Farmer Tractor, Self-propelled Wheat Harvester and so on, offers one of the most complete lines in the industry.

Product Categories : Corn Harvester > Four Rows Corn Combine Harvester

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.